It has been a while since automation became commonplace in modern businesses and workplaces. Though revolutionary in eliminating error-prone tasks and freeing human staff from the mundane, businesses are repeatedly warned of the automation paradox. It is the idea that dictates that as automated systems become more efficient, the dependency on human resources increases. In the manufacturing industry, where automation is integral, and talent resources are scarce, ERP automation or ERP systems with AI and powerful machine learning (ML) will be the game changer!

Our expert ERP consultants like to think of ERP automation as the proverbial two-for-one. We traversed through the ongoing talent shortage in the manufacturing industry, among other pressing challenges in 2024. Even though the industry continues to have a high hiring appetite, manufacturing companies struggle to retain and optimize their talent pipeline amid rising costs. Recession fears and the need to readapt to the return to work-to-office trends also add to the talent decline.

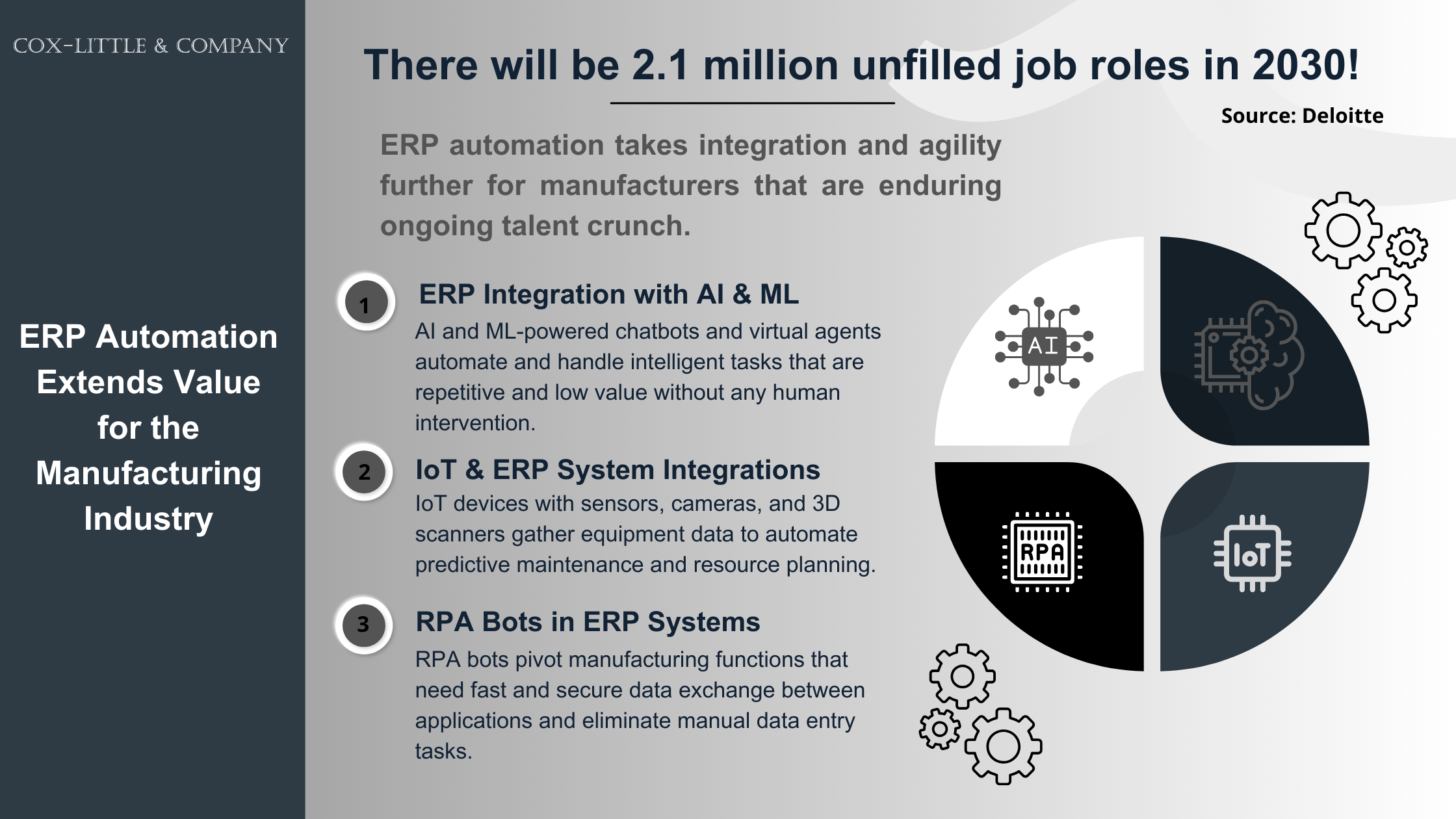

According to Deloitte and the Manufacturing Institute, by 2030, US manufacturing will be left with 2.1 million unfilled jobs. The research also found that diversity, equity, and inclusion (DEI) have emerged as an employment imperative for the industry to achieve desired business benefits.

Additionally, with young talent joining the workforce, manufacturers are pressured to maintain balanced skill composition by making jobs more creative, innovative, and flexible. Packed with advanced predictive analytics and decision-making capabilities, ERP automation helps transform manufacturing businesses and factories into intelligent and independent units, addressing talent retention and attrition issues.

Let’s explore ERP automation and its benefits to a manufacturing business grappling with tight labor shortages.

What is ERP Automation?

Automation in the era of GenAI has climbed an unmatched stage of transformation, paving the way for hyper-automation. ERP Automation refers to integrating AI, machine learning algorithms, internet of things (IoT), and robotic process automation (RPA) into ERP software. It helps enterprises to function in the digital space driven by informed decisions, enhanced data integration, and real-time workflow and process insights. By replacing traditional processes with ERP Automation, manufacturers can automate all manual, repetitive, and time-consuming tasks. They can make those tasks error-free and improve performance efficiencies with timely actionable insights.

Think of ERP automation as a special cable connecting business data, processes, and workflows that seamlessly filter and securely dispense data to departments and stakeholders in need. The most common use case of cloud ERP automation is integration across departments such as accounting, HR, finance, inventory, distribution, warehouse management, and CRM systems for centralized view. Stakeholders and team will be able leverage automated data entries, report generation, KPIs tracking, real-time inventory, and stock level monitoring, and much more.

These capabilities resemble ERP systems’ essential integration capability. To know what makes it more different, our experts have simplified ERP automation with examples from real-world scenarios:

ERP Integration with AI and Machine Learning: Customer service automation is the most recent and successful example of AI-led automation. With intelligent chatbots and virtual agents, businesses address inbound customer service requests without relying on human staff. By leveraging AI’s voice recognition and interaction features, customer service departments can hold intelligent conversations, authenticate callers, and proactively resolve customer issues at scale. If there is a peak in inbound inquiries or seasonal demand, businesses can handle the volume of requests without hiring or training additional customer service staff.

Imagine the same scenarios for a global manufacturing brand. By integrating AI-powered tools for customer service automation, they stay ahead of changing customer expectations. By integrating learning, decision-making, personalization, and reasoning capabilities into their CRM platforms, they can make the overall process free of any human intervention.

Additionally, they can generate insights and analyze customer sentiments using natural language processing (NLP) to reiterate customer experiences. With automated reporting and forecasting, the manufacturing brand can go the extra mile with personalized recommendations based on feedback, satisfaction levels, and product or service quality.

IoT Integration with ERP Systems: IoT-enabled devices on the manufacturing floor have sensors, high-definition cameras, and other tools that gather insights on the state or quality of machinery and levels of inventory, stock, and supply chain. In real-time, maintenance and other relevant departments are notified about potential repairs, stock shortages, energy consumption levels, and equipment damage data. These data points allow for predictive and preventive maintenance. It can collate staff behavior and team trends to plan and facilitate production and asset management decisions while reducing operating costs.

RPA in ERP Applications: RPA integrated into ERP systems pivot functions that require seamless data exchange between different enterprise applications.

For instance, if a manufacturer purchases new floor equipment, the data of its purchase, warranty, and maintenance information can be shared with finance and maintenance teams to track expenditures, purchases, and repairs. Suppose the manufacturing company recruits a new team, the hires’ salary and banking information is exchanged from the HR portals to the finance, payroll and banking applications. This helps automate processes like crediting salaries, renewal of contracts, deduction of taxes, pay slip generation, etc. The automated data exchange between systems and ERP platforms is driven by RPA. Since there is no requirement for manual data entries, these types of task automation are error-free and are carried out like clockwork!

Using RPA bots, manufacturers can track contracts, ledgers, legal documents, material and equipment purchases, employee performance, and other information across units and plants without human involvement. They can personalize their marketing outreach or supplier and distributor partnerships by sending mass emails periodically.

ERP Automation Benefits to the Manufacturers

Many cloud-based ERP systems offer customizable features that allow manufacturing companies to tweak any process with automation so they can focus on product and production innovation. Today’s ERP systems powered by AI, ML, RPA, and IoT integration are within the reach of manufacturers. They do not require high upfront costs or radical infrastructural investments. ERP automation guarantees a variety of benefits such as:

- Lower Operating Cost: ERP automation helps manufacturers scale their production workflows or business confidently without hiring large teams. Automation enables them to achieve productivity and performance even while operating with a lean workforce and lower operating costs.

- Higher Accuracy: Manually run tasks always carry the risk of misappropriations and mistakes that lead to wastage. AI-driven bots and RPAs in ERP systems automate all complex tasks without the risk of human errors.

- Higher Performance Efficiency: ERP automation reduces the reliance on human staff to perform low-value, repetitive tasks. It helps manufacturers use their human resources in meaningful areas to drive innovation, higher financial outcomes, and better productivity and performance efficiencies.

- Informed Decision Making: Advanced data analytics and AI-driven predictions enable manufacturers to decide better about their resource allocation, production plans, product design, and other critical decisions to improve the top and bottom line.

- Streamlined Workflows: ERP systems with superior automation make the manufacturing process more streamlined by providing real-time visibility into processes, departments, and assets. It helps unveil issues and hindrances to profitability, production efficiencies, wastages, and more to eliminate their causes. ERP automation is integral to making the entire manufacturing value chain streamlined.

- Lower Carbon Footprint: ERP automation not only helps make processes people-free but also paperless. From handling digital transactions and disseminating data across systems and applications on time, these systems help manufacturers reduce their carbon footprint. Additionally, they help implement sustainable initiatives by reducing wastages, optimizing resources, and making the most of the supply chain and logistics.

In conclusion, if ERP systems stand for agility and integration, automation takes them further to reach unprecedented levels of productivity and profitability. Amid the ongoing skilled labor shortage in 2024 and the ambition for smart factories over the next five years of 70% manufacturers, ERP automation will remain a positive proponent.

Our ERP experts can get you to know more about navigating the manufacturing ecosystem fraught with talent shortages. Moving ahead with well-curated ERP project decisions can be a real problem solver with the right ERP talent.

Let’s get together to plan and understand your ERP staffing needs for 2024. Contact our team for more details.

Leave A Comment