Global manufacturers may agree that 2023 was more like a game of chess. Manufacturers had to carefully maneuver several business, economic, and tech uncertainties that began seizing the middle. But the volatility continues to get higher in 2024. Manufacturing businesses must gear up to tackle sharp talent attrition rates and climate-induced supply chain disruptions.

It’s not the end of the world. It’s just another year with newer challenges! ERP software solutions have taken center stage in the manufacturing industry for years by offering robust functionalities and real-time insights to fuel performance and profitability. The modern, upgraded versions of cloud ERP systems packed with advanced data security, AI-driven predictive analytics, task automation, IoT integrations, and personalized and user-friendly dashboards will help assuage labor shortage impacts in the industry.

Recently, Gartner’s 2024 Tech Trends in Manufacturing survey found that 54% of manufacturing companies plan to increase their software spending by 10% this year. Most of the software purchase decisions of U.S. manufacturers have been around business intelligence (BI) and data analytics. Enterprise resources planning (ERP) solution was also among the spending priorities. However, 47% of manufacturers feel that picking a suitable technology is the most challenging part of planning their new software investments. These findings highlight the need for software vendors to recalibrate their messaging and brand awareness to influence their target buyers. But for manufacturing businesses, this is a surefire sign to trust ERP consultants or solution experts to help plan and optimize ERP projects.

Amid the continued pressure to embrace approaches like smart factories, net-zero, industrial metaverse, GenAI, and clean technologies, ERP software for manufacturing provide a good defense strategy! Now, let’s examine the critical trends in manufacturing for 2024.

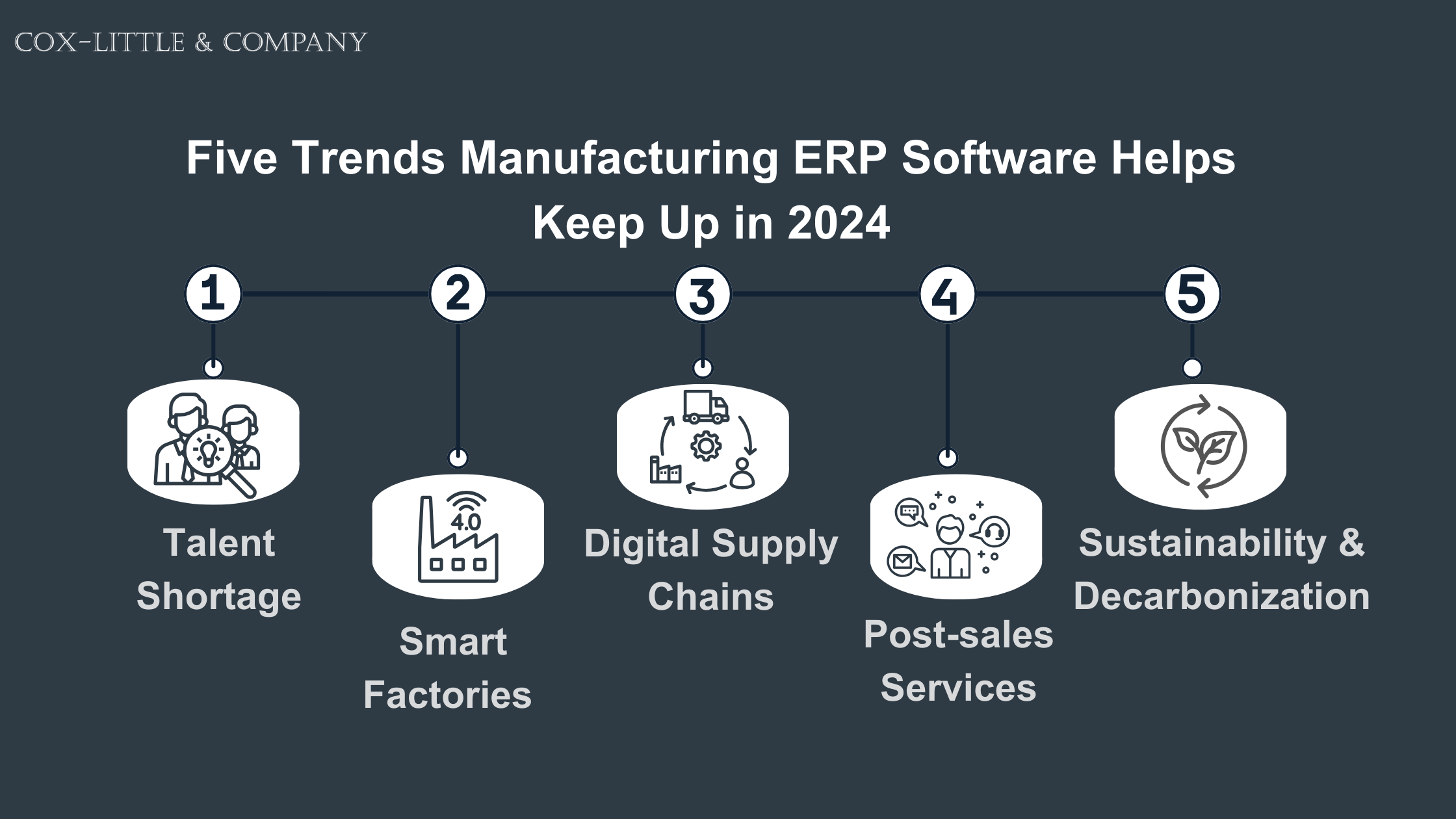

Five Critical Trends ERP Software for Manufacturing Helps Embrace

1. Severe Talent Shortage:

Great Resignation affected the manufacturing industry the most. A Deloitte report estimates that the industry is predicted to record 2.6 million job losses in the next few years from attrition and retirements. This would mean a significant uptick in talent and skill shortages and employee burnout. Additionally, three-fourths of manufacturing executives find attracting and retaining quality talent challenging, according to a recent National Association of Manufacturers (NAM) survey.

As the talent gaps continue to widen in 2024, digital tools enabled by innovative technologies like AI and GenAI are deployed by the manufacturers to monitor the industry pulse, record shifts in employment trends, and track the overall costs of training and upskilling. Combining digitization and automation can address these requirements. It helps augment manufacturing processes and production workflows without human intervention.

ERP Helps Counter Talent Shortage:

ERP systems integration capability is like the Sicilian defense move in chess. ERP automation or integrating ERP software with AI and machine learning helps perform tasks independently of human resources. It helps execute tasks that are repetitive, low value, or dangerous and unsuitable for workers to perform on factory floors. It can also automate functions that require decision-making powered by data integration, unique algorithms, and predictive analytics. The outcomes of automating ERP software for manufacturing are end-to-end. Meaning manufacturers can implement automated production planning and scheduling, sales forecasting, inventory tracking and predictions for storage optimization, and more, without any dependency on human factors.

2. The Smart Factory Phenomenon:

The confluence of 5G, AI, Internet of Things (IoT), advanced data analytics, and cloud computing, promises greater agility, scalability, and visibility in manufacturing and production units. Combining these technologies initiates smart factory concepts across manufacturing verticals. The Deloitte study found that 83% of manufacturers believe smart factory will transform production in the next five years. Additionally, smart factory technologies will be pivotal to the industrial metaverse that would require further advancements and investments. For more immersive experiences in smart factories, 3D modeling, 3D scanning, and the digital twins will facilitate manufacturers tap into unlimited possibilities.

ERP Enables Smart Factory Concept

Smart factory features include flexibility, automation, process and systems integration, real-time, reliable data analyses, and sustainable production. ERP software for manufacturing are built to facilitate real-time data access and analyses to drive decisions that favor sustainability, performance, and profitability goals. Task and process automation with ERP systems helps reduce cost, and integration with IoT devices helps identify and prevent inefficiencies, wastage, and resource downtime. Manufacturers can build flexibility by creating centralized ERP environments to respond to dynamic market challenges and customer demands. All in all, cutting-edge ERP solutions drive value to transform traditional manufacturing floors into smart factories.

3. Digital Supply Chains:

Global supply chain disruptions and semiconductor shortages caused due to the worldwide lockdown during the COVID-19 pandemic drove manufacturers to rethink strategies. Manufacturers found opportunities to do more with less through digitization across processes and departments, including the supply chain. In the post-pandemic world, economic uncertainties became the reason to digitize supply chains. Moreover, growing regulatory concerns about sustainability have also driven manufacturers to opt for a digital pathway to keep their raw material sourcing and supply chains verifiable, ethical, and easy to track.

ERP Enables Digital Transformation in Supply Chain

Modern and robust ERP software for manufacturing guarantee efficiencies go beyond conventional labor-intensive processes in the supply chain continuum. For example, ERP systems help maintain current and historic sales, demand, production, and delivery data. It simplifies demand planning and forecasting based on trends and patterns. ERP software eases stakeholder collaboration by bringing together partners, vendors, distributors, suppliers, sales executives, customer success teams, and marketing departments. It builds a single source of truth to collaborate data, documents, and stakeholders to digitize the overall supply chain.

4. Post-sales Services for Competitive Benefit:

It is evident that consumer expectations have evolved, and manufacturing businesses need to capitalize on customer loyalty to keep up with their revenue objectives. Aftermarket or post-sales customer service is an essential area for competitive differentiation. As per Deloitte’s analysis of publicly available industrial reports, there is an accelerated interest in aftermarket services.

AI-led customer service automation, AR and virtual reality (VR)-based troubleshooting, and other enhancements in aftermarket service are adopted by leading manufacturers. These services drive 2.5 times higher operating margins, improve customer experience, and create opportunities for upselling and cross-selling.

ERP Systems are Tailored for Aftermarket Success

ERP integration with customer relationship management (CRM) systems, sales, and other enterprise platforms integrate business-wide information. It helps speed up the sales cycle, provides insights into opportunities to elevate customer satisfaction, automates contract renewals, billing, and invoicing, and forecasts repairs and maintenance orders. An ERP expert can help implement the right ERP software for manufacturing with the integration best-practices between platforms to improve customer and aftermarket services.

5. Decarbonization in Manufacturing

Sustainability initiatives to lower carbon footprint and phase out fossil fuels with clean energy alternatives are now a worldwide goal. The manufacturing industry has the largest scope to transition towards electrification and decarbonization goals. But the journey is an easy, overnight flip. There are challenges to identifying and collaborating the right stakeholders, understanding regulatory obligations, and embracing low-carbon alternatives. Nonetheless, there have been strategic partnerships and investments to scale sustainable manufacturing initiatives.

Cost and wastage reductions are key sustainability metrics. ERP software for manufacturing boasts of core value proposition in improving efficiencies that contribute to sustainability. ERP software allows for streamlined logistics, fuel, resources, power, and fleet optimization. It helps deliver actionable data insights to embed sustainability into product design, manufacturing, supply chain, and distribution.

ERP for Manufacturing: The Best Move of All Time

In 2024, we are at the forefront of immersive technologies, clean energy project investments, and customer-focused product and service innovations. Like the game of chess, it is easy to lose sight of the objectives when there are obstacles. And as more and more advancements pile up, there is also the fear of falling into the legacy loop.

Manufacturers can strive to seize control of their business while COX-LITTLE & Company’s ERP staffing services help provide the desired levels of stability with relevant ERP expertise. Our pre-vetted ERP experts believe that the best defense technique is gaining control of the entire value chain through ERP optimization.

We will help empower your internal IT teams with the tactical knowledge of ERP software for manufacturing, add-on features and functions, and modules to improve operations and impact bottom-line. While you focus on evolving at the pace of industry trends, COX-LITTLE’s ERP staffing solutions will manage all the nitty-gritty of rolling out a cost-effective and nimble ERP platform.

Tell us about your ERP priorities for the quarter today. Follow this space for more updates about ERP software for manufacturing. In the meantime, connect to talk to our experts.