Vehicle Manufacturers can finally move over multiple manufacturing systems and platforms. Because their search ends with cutting-edge automotive ERP software!

Many years ago, when Elon Musk declared that autonomous driving would become mainstream, it was perceived as a far-fetched AI fantasy. Today, AI in automotive manufacturing is more than self-driving cars. The world has come to a collective consensus that the automotive industry shouldn’t be behind in exploring intelligent shifts powered by AI capabilities readily available in custom automotive ERP systems.

ERP platforms provide a bird’s eye view and in-depth centralized data insights which facilitate decision-making across operations to improve production planning and quality. With the know-how of experienced ERP professionals, automotive manufacturers can amplify the impact of automotive ERP software while harnessing AI capabilities across multiple use cases. First, let us have a look at the automotive technology market overview and other industry trends to understand the opportunities ahead.

It is evident that customers and climate impact chains will also dictate global mobility habits. For the U.S. automotive industry, the worst is nearly behind. Despite diminishing electric vehicle (EV) sales, supply chain disruptions, increasing material costs, and factory strikes, the industry recorded a double-digit growth rate of $90 million from commercial vehicle sales in 2023. New research conducted by PwC suggests 2024 will be the year known for electrification, autonomy, sharing, connectivity, and yearly updated trends. However, catching up with these trends requires adopting a more tech-savvy approach towards automotive production, like smart factories and novel sustainability concepts. Gazing through the automotive ERP lens, optimizing performance and adopting innovative manufacturing transformations will be a cakewalk.

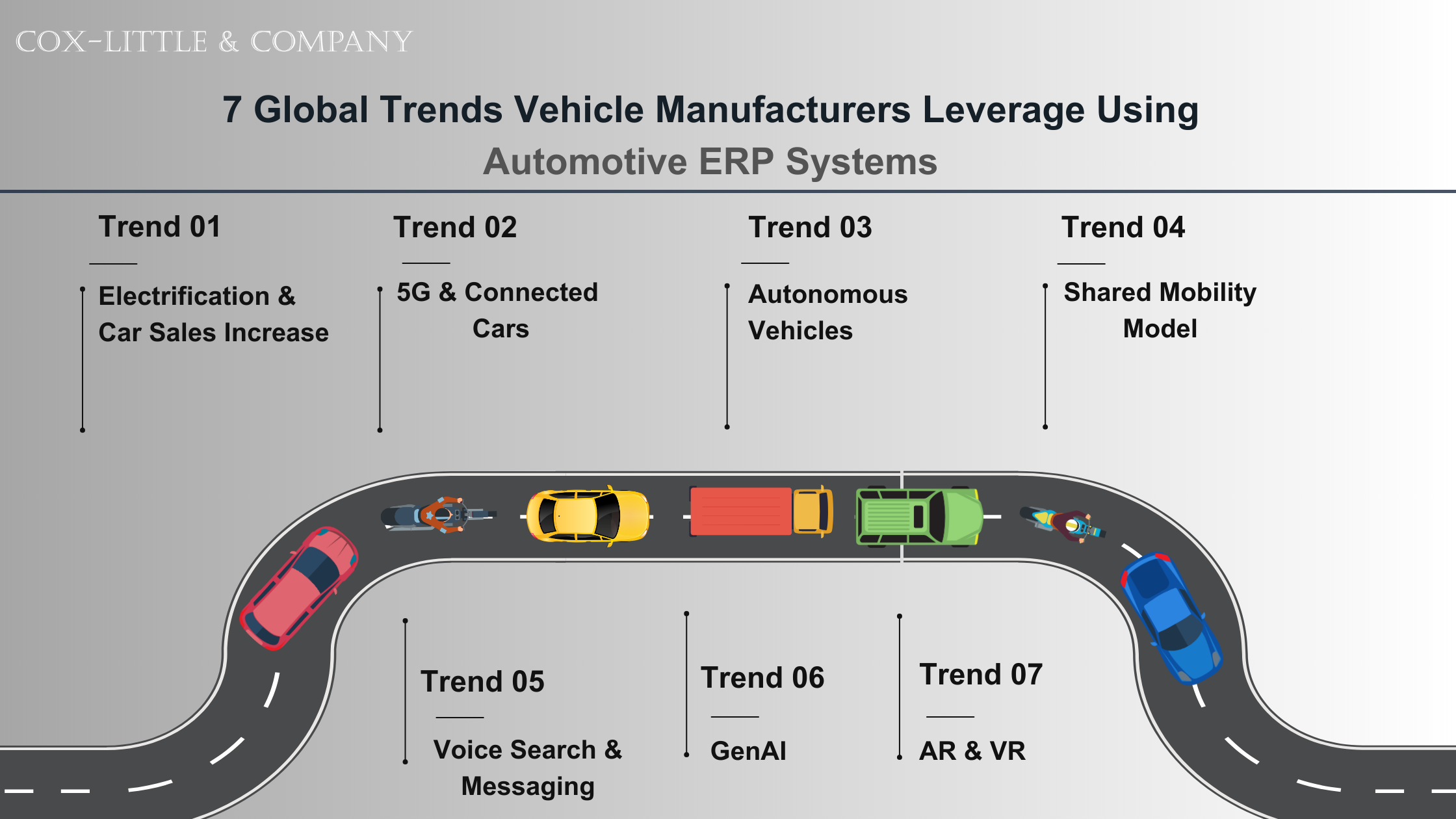

Below are the line-up of trends transforming the global vehicle manufacturing industry:

- Electrification & Increase in Vehicle Sales : According to the Global EV Outlook 2023 by the International Energy Agency, during the first quarter of 2023, almost 2.3 million EVs were sold. EV sales in the U.S. will increase by 16% compared to the last year’s 64% growth rate. The slowdown is attributable to several factors, like insufficient charging facilities, poor incentives, and market oversaturation. To keep up the sustainability momentum, governments, and original equipment manufacturers (OEMs) are investing in EV charging infrastructure and incentivizing EV adoption with subsidies. On the other hand, global online car sales are set to hit 7.3 million units by the end of the first quarter. The market for used vehicles in the B2C segment is predicted to increase by 50% in North America.

- 5G & Connected Cars: To augment driver experiences like intelligent navigation, infotainment systems, data transfers, and top-notch communication features, 5G adoption in the automotive space is driving the connected cars revolution. Many start-ups are now dedicated to improving vehicle connectivity solutions. Vehicle-to-vehicle (V2V), electric vehicle grid (V2G), and public infrastructure (V2I) are examples of connectivity solutions currently being improved to facilitate data exchange. As per the recent Statista report, the total count of connected vehicles in the U.S. will likely exceed 150 million by 2025. However, on the flip side of 5G connectivity lurks cybersecurity risks, like ransomware attacks, infiltration of vehicle infotainment systems, and hacking, calling for increased encryptions and cloud security.

- Autonomous Vehicles: While autonomous or self-driving cars are yet to become a common sight on the road, 2024 is when automotive manufacturers will experiment and add advanced driver assistance systems (ADAS) features. Adding these features to new cars and vehicles will help reduce the risk of road accidents and improve driver safety.

- Shared Mobility Model: Adding to the trend of reducing carbon footprint, shared mobility business models are growing in popularity. Shared vehicle rentals and hailing services catering to short-term travel needs curb lower carbon emissions and provide affordable alternatives to vehicle ownership and new vehicle manufacturing.

- Messaging Apps & Voice Search Features : Another exciting trend in the automotive industry is upgrading customer service with chatbots and messaging apps powered with intelligent voice search features. They help manage the influx of customer queries at the pre-sales stage without exhausting customer service staff. The AI-enabled messaging apps and digital voice agents help make maintenance, and post-sales services more streamlined and efficient, improving customer satisfaction levels.

- GenAI in Vehicle Manufacturing: GenAI is already impacting the automotive manufacturing industry, proving its value creation in vehicle design by generating realistic and complex images, video simulations, text, and audio. Voice assistants in vehicles for driver assistance also hold the potential for scaling performance across repairs and diagnosis, sales, marketing, and customer service. A study by Boston Consulting Group found that many customers prioritize the overall quality of the car-buying experience. However, only 52% of customers are fully satisfied with their recent car-purchasing experience. GenAI’s intelligent reasoning gives OEMs and automotive dealers the leverage needed to tailor user experience. Additionally, GenAI has excellent scope, giving deep and accurate insights into the customer base making it easier to understand the buyers’ journey allowing for the hyper-personalization of marketing and sales outreach.

- AR and VR: Using augmented reality (AR) and virtual reality (VR) to experiment and research with interactive digital simulations of the real world isn’t a new concept for automotive manufacturers. What is new, is these technologies have undergone tremendous advancements in recent years at a much faster pace These advancements are allowing manufacturers and dealers to visualize end-to-end from design to delivery. Some renowned automobile brands have taken a step ahead of competitors by delivering superior driver experiences. One of these being the ability for customers to visualize and virtually test-drive vehicles, helping aid their buying decisions. These trends will likely gain more momentum and be a competitive differentiator this year.

10 Ways Automotive ERP Platforms Improve Vehicle Manufacturing

The trends mentioned above represent one aspect of the current automotive manufacturing revolution shaping how customers will engage with their vehicles. ERP systems are the backbone for automotive manufacturers to successfully keep up with these trends in today’s hyper-competitive market. Below are ten scenarios where automotive ERP software will be a tremendous value-add in the vehicle manufacturing industry:

- End-to-end Supply Chain Monitoring: Every manufacturer would gain from a real-time view of the supply chain. Real-time tracking and monitoring of the delivery of material components and resources from manufacturers to assembly lines enable production planning without delays and oversights. It helps enhance logistics operations and streamlines the manufacturing processes for the timely delivery of automotive parts or products. For example, an EV manufacturer can leverage the automotive ERP platform to track the movement of charging cables, sockets, gearboxes, and other impact parts from the source until it reaches the factory floor.

- Production Planning & Execution: Once the manufacturer procures the materials and equipment, the next step is planning resource allocation, work orders, and the production process. The planning stage involves considering the average time required for production, probabilities of downtime and wastage from errors, changes to production operations, and resources. The goal is to ensure the production deadlines are met with quality products at minimal operating cost and higher profitability. An automotive ERP system merges data from all relevant sources to execute the production process as per plan and production efficiency.

- Inventory Management: Automotive manufacturing companies deal with an exhaustive list of inventories that are disbursed across departments. Using industry-ready ERP software simplifies maintaining inventory data to provide an accurate picture of the quantity to avoid resource shortages and handling and carrying costs so that there are enough vehicle parts and components in stock.

- Quality Assurance: Automotive manufacturers must live up to customers’ expectations regarding quality and reliability. Automotive ERP systems’ integration capabilities help connect processes and workflows to quality checks to spot production defects and uphold high-quality standards.

- Financial Management: Automotive manufacturers also aim to make the production process financially lean and cost-efficient. Automotive ERP software simplifies the management of end-to-end financial processes and resources across accounting, planning, and reporting. It helps automakers get a comprehensive view of financial data from several departments, including sales, production, supply chain, customer services, marketing, and more. Additionally, today’s ERP systems have built-in features that allow compliance with international accounting standards.

- Customer Relationship Management: Customer service is a gold mine of opportunities for automotive manufacturers and ERP systems help positively impact customer satisfaction levels. An automotive ERP system can provide insights that help pivot innovative and personalized marketing initiatives when integrated with CRM systems. This involves brand differentiation, increasing sales leads, building more engaging sales strategies, managing customer relationships, and elevating experiences throughout the purchasing journey.

- Regulatory Compliance: With the recent emphasis on sustainability and conscientious manufacturing, the automotive industry is subject to new regulations that include carbon emission rates, worker and environmental safety, and more. Automotive ERP systems help keep track of the latest regulatory norms and check if the manufacturing processes are aligned with the compliance goals and practices. Using AI and GenAI capabilities, it helps automate reporting, governance workflows, and other processes to steer clear of compliance defaults and legal penalties.

- Real-time Data Analytics: ERP systems built on superior data analytics and reporting capabilities are game-changing tools for automotive manufacturers to be more decision-driven and get a hold of real-time data. Being data-driven helps leverage all processes across the value-chain such as resource allocation, managing the operational output, and supporting strategic decisions tied to improving top-line and bottom-line.

- Warranty & Service Management: In the automotive industry, keeping track of the warranty and service management helps improve customer satisfaction, brand loyalty, and warranty agreement compliance. Customers prefer automotive dealers to take the initiative of reminding them of warranty due dates, upcoming repairs and maintenance, and set automated servicing schedules. ERP systems that can send auto-updates to the respective departments and coordinate with repairs teams every time a customer raises a request to fix vehicle problems.

- Equipment & Asset Management: To avoid wastage and maximize the equipment and asset lifecycle including production resources, tools, materials and physical equipment, ERP systems enable real-time updates. It aids automotive manufacturers with better planning, cost reduction, resource maintenance, and upkeep to improve delivery of quality products. ERP platforms help monitor and maintain the assembly line equipment, to ensure there are fewer instances of operation and production downtime.

Talent Shortage is not the Dead End. That’s Why ERP Consultants Matter

ERP systems are becoming more industry focused. However, there is a need for talent resources that can cater to the niche areas of automotive ERP systems to unlock a platform’s full potential. ERP consultants for the specialized section of automotive manufacturing help solve every automotive manufacturer’s dilemma—to focus on production speed or invest time and resources to unravel an automotive ERP software.

COX-Little’s ERP experts have experience helping manufacturing companies across industry verticals sustain their competitiveness in the volatile market grim with complex regulatory norms, rising customer expectations, and constantly evolving technologies.

We cater to all your talent requirements at every ERP lifecycle stage from ERP software selection, implementation planning, customization, application or system integration to on-prem to cloud ERP upgrades. Get in touch with us to know more about planning your IT staffing needs for the year.