Global usage of QR codes peaked in the contactless era of COVID-19 pandemic and remains a preferred method for digital payments. According to research, QR code usage between 2021and 2023 grew by 323%. GS1 Sunrise 2027 initiative aims to take the omni-directional and smart phone accessible QR code advantage further in the manufacturing, retail, and supply chain industry. However, testing piloting 2D code projects as per GS1 standards requires deep considerations about several variables such as tools, stakeholders, KPIs, investments, cost drivers, and impact across data and IT touchpoints.

In this blog, we will explore the merits of QR codes for product labeling and the end-to-end impact on data and IT systems for adopting GS1 QR codes.

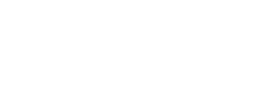

7 Ways 2D QR Code is Better than 1D Barcode

Primary reason to replace 1D European Article Number (EAN)/ Universal Product Code (UPC) with 2D Quick Response (QR) code is the data capacity. QR codes are ideal for coding exhaustive product information that will be accessible for all stakeholders across the value chain. Higher character capacity of QR codes allows for encoding and addition of data on the go. This feature presents unique advantages to users across the retail, manufacturing, supply chain, healthcare, financial and banking services, advertising, and product packaging industries. The primary merits are:

- Easy Capitalization of Smart-phone Accessibility: From the users’ perspective, QR codes are convenient because they can be scanned using a smartphone camera. According to 2024 Statista reports, there are about 310 million smartphone users in the U.S., and implementing QR codes helps leverage smartphone penetration across the nation.

- All-in-one Data Source: QR codes have editable URL links, landing pages, and product information that can be dynamically added, edited, and accessed for detailed product data. It is a one-stop-shop for embedding product data in formats that include but are not limited to product codes, images, audio, and documents for certifications, authenticity, nutritional facts, licenses, sourcing, safety information, hazard warnings, promotional details, storage specifications, and recycling or disposal instructions.

- Online and Offline Customer Engagement: Retail firms can leverage the black and white squares of QR codes and DataMatrix in their advertising and brand promotion strategies by sharing them on online and offline mediums.

- Real–time Inventory Management: QR codes allow for error-free and real-time monitoring of retail merchandise and stock levels which are essential for managing inventory movement, storage management, tracking product expirations, and reducing wastage.

- Product/Inventory Tracking & Demand Forecasting: Keeping track of the products by scanning QR codes across the supply chain journey helps update all stakeholders across the distribution channel including the end-user or customer. The end-to-end traceability enabled via QR codes on packaging and product labels supercharges logistics and supply chain management, providing data-driven insights for demand forecasting.

- Smart Packaging: QR codes help make the ideal use of the space on product labels and packaging. A quick scan is enough to gain necessary information about the product across the supply chain that will be relevant for earning customers’ trust, satisfying regulators’ compliance requirements, and informing other stakeholders with supply chain, inventory, and logistic data.

- Promotions and Advertising Campaigns: QR codes are also an interactive medium of building direct brand-to-customer relationship with engaging brand advertising, promotional, and feedback initiatives.

GS1 2D Pilot Toolkit for Planning Testing and Migration to 2d QR Code

The international organization, Global Standards 1 provides standards for managing, developing, and implementing barcodes for unique and reliable product identification. GS1 is also the official provider of Global Trade Item Number (GTIN), EAN, and UPC. The GS1 Sunrise announced setting the end date for retailers to equip their POS systems with scanners that can read both 2D barcodes (QR codes or DataMatrix) and traditional barcodes. The organization is assisting organizations at the demand and supply-side as well as solution providers for 2D code migration. The 2D pilot has already begun in 48 countries.

Below are some of the specifications from the GS1’s 2D pilot toolkit that will be relevant for retailers, manufacturers, and brand owners:

Difference between QR codes, DataMatrix and GS1 2D barcode

2D barcodes include QR codes and DataMatrix. A QR code is equipped with readable 2D codes and has three-pattern squares towards the edges. DataMatrix includes readable 2D codes resembling light and dark patterns within a square that can be scanned from any direction. In appearance DataMatrix is noticeably different compared to QR codes and has L-shaped pattern around the corners and is also slightly smaller in size.

GS1 QR code adheres to GS1 specifications for sharing detailed product information on the packaging like lot number, product ID, and product quantity. When it comes to dimensions and character count that GS1 QR code is the same as QR codes. Both QR code and DataMatrix must be printed in black against a white background.

The GS1 standard mandates ISO/IEC 646 for encoded data within DataMatrix. The default character limit is supported by all computer systems.

What is the possible impact of barcode to GS1 2D QR code transition?

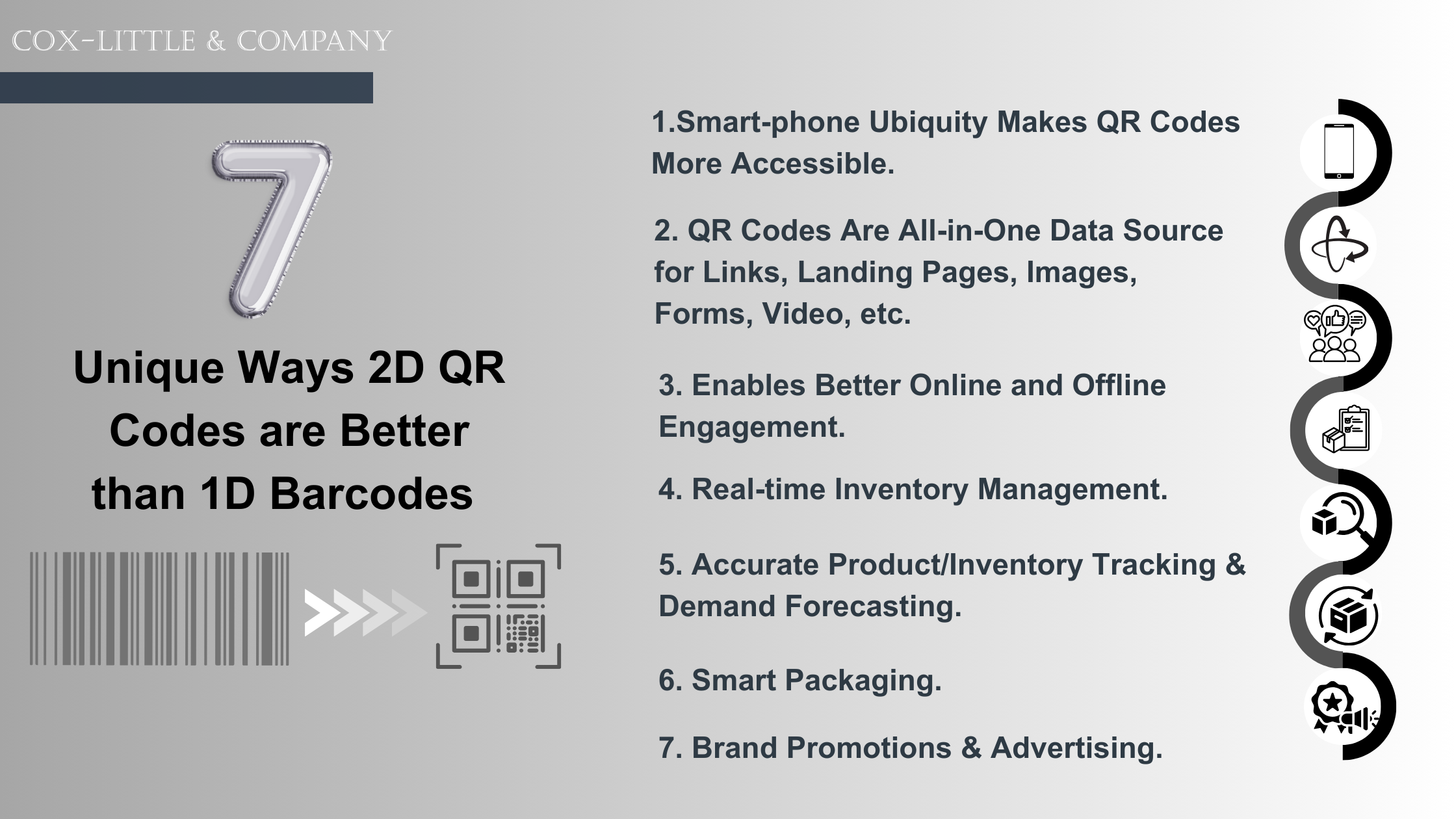

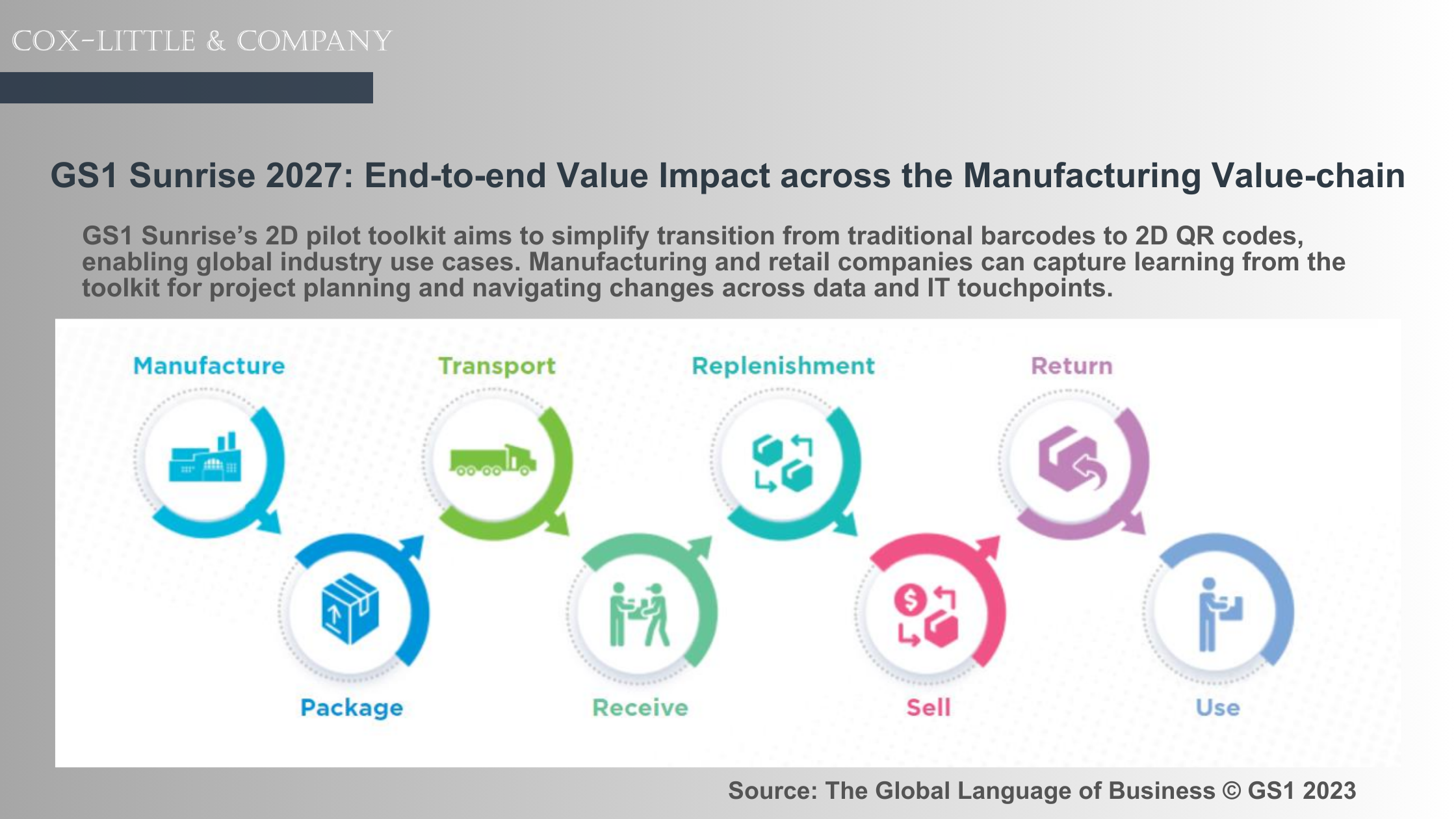

The GS1 2D pilot toolkit offers a 360-degree view on the impact of the migration. The toolkit document also emphasizes analyzing the end-to-end value chain impact to make sure organizations do not overlook critical steps and stakeholders in the project plan. It considers seeking technical, operational, and organizational insights for effective planning and execution to understand the potential impact across data and IT touch points.

For illustration, let us consider ABC, a manufacturing conglomerate in the perishable consumer products industry that also oversees product packaging. Like most manufacturing brands, ABC could be a user of on-premises enterprise resources planning (ERP) software and 1D barcodes for scanning inventory and products. The 2D pilot will initiate the below changes across ABC’s manufacturing value-chain:

Moving with the pace of change often requires insights of subject matter experts like implementation project managers, IT systems configurations and customization experts, QA and testing professionals, post-production support, etc.

If you are looking for talent resources to make your enterprise’ 2D pilot successful, we can find the right professionals. At Cox-Little & Company, we know how to empower enterprises and their teams with high-caliber candidates and qualified professionals without the hiring overkill.

Do you want to explore Cox-Little’s flexible staffing models for your ERP and legacy IT projects? Contact our industry-leading staffing and consulting team!